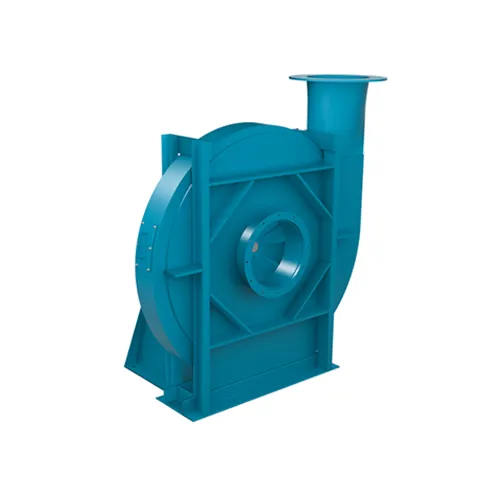

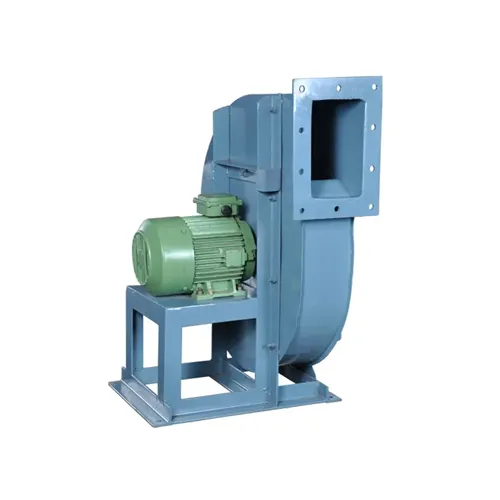

Multi-Cyclone

We are Manufacturer, Supplier, Exporter of Multi-Cyclone from Pune, Maharashtra, India

Multi Cyclone Powder Recovery Systems are advanced filtration units designed for high-efficiency powder separation in industrial applications. These systems consist of multiple cyclone chambers that enhance separation efficiency by utilizing centrifugal force to capture fine powder particles from the air stream.

Manufactured using MS (Mild Steel), SS (Stainless Steel), and AL (Aluminium), they offer excellent durability, corrosion resistance, and long service life. Multi Cyclones are widely used in powder coating plants, pharmaceutical industries, food processing units, and various dust control applications.

The modular design ensures enhanced particle recovery with minimal pressure drop, leading to improved operational efficiency and cost savings. These systems provide a reliable and eco-friendly solution for powder recovery, reducing material wastage and maintaining a clean working environment.

- High-Efficiency Powder Recovery: Utilizes multiple cyclone chambers for superior separation.

- Robust Construction: Made from MS, SS, and AL for enhanced durability and corrosion resistance.

- Optimized Aerodynamic Design: Ensures maximum separation efficiency with minimal pressure drop.

- Modular & Scalable: Designed to accommodate various industrial applications.

- Easy Installation & Low Maintenance: Reduces downtime and operational costs.

- Enhanced Powder Recovery Rate: Minimizes material wastage and maximizes cost savings.

- High-Volume Handling: Efficiently processes large airflow with fine particulate separation.

- Customizable Design Options: Tailored to specific industry needs.

- Powder Coating Plants: Ensures improved powder recovery and reuse.

- Pharmaceutical Industries: Supports fine powder separation and dust control.

- Food Processing Units: Provides hygienic powder recovery and air filtration.

- Chemical & Petrochemical Industries: Enhances powder collection efficiency.

- Cement & Construction Materials: Maintains dust-free operations.

- Metal & Plastic Industries: Assists in recycling and process optimization.

- Textile & Dyeing Industries: Recovers fine powder and pigments effectively.

- Industrial Air Filtration & Pollution Control: Promotes cleaner work environments.